‘Field’ simulator, an interactive 3D virtual reality

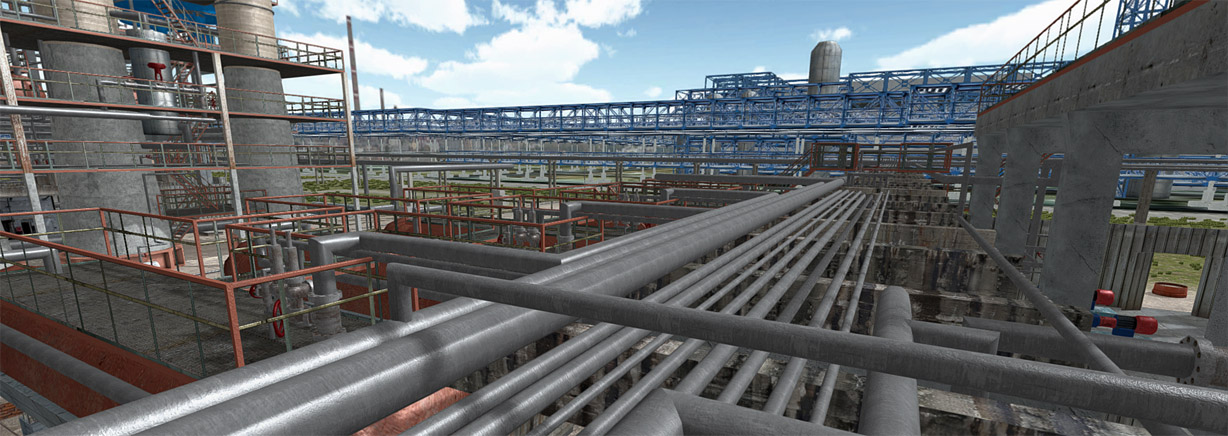

The interactive 3D model of the technological object associated with the dynamic mathematical model of the technological process encompasses all the elements of the equipment being a part of the oil refinery or chemical technological unit and provides unlimited opportunities for practicing the operators’ skills required for working ‘in the field’.

Full compliance with the actual location of objects, photorealistic textures, interactive controls and realistic visualization of the equipment response to the impact create an environment that is as close to that in which the personnel being trained work every day as possible. Training in such conditions is thought to be the most effective method and it significantly raises the complex training level of specialists.

When developing a 3D ‘field’, the T-Soft specialists use the latest advances in 3D design. This allows visualizing complex technological units in real time without loss of speed and display quality.

Object management

To manage the technological process in the 3D environment, interactive controls are implemented that are visually completely identical to the actual ones.

All manipulations of the control elements receive the system feedback in the form of changing the technological process parameters and the changes visualization.

Instrumentation visualization

Instrumentation visualization allows monitoring technological process parameters in real time. It is convenient, that one can see the indicators in a pop-up window. Both scales and measured parameters of all measuring instruments correspond to the actual ones.

Equipment reaction visualization

The advantage of the virtual 3D model is the ability to visually simulate catching a fire and an explosion, as well as depressurization of both technological units and pipelines. The 3D module provides visualization of the main emergency events that the instructor had included in the simulator exercises. Thus, the 3D visualization mode is thought to be most suitable for practicing actions to control off-nominal and emergency situations in an environment being as close to the actual one as possible.

3D application supports the use of all contemporary 3D glasses, headsets and helmets, their use being an important factor for the psychological training of operators.

Unit behavior analysis

The T-Soft specialists have developed and tested solutions that allow the use of spatial simulation technologies to enable the simulator complex to provide situations especially for oil refineries and chemical plants. The simulator complexes with a 3D ‘field’ make it possible to calculate, assess and visualize the behavior of the technological unit in the following operation modes:

- normal (regular) operation mode;

- cold start and warm start of the unit;

- scheduled and emergency shutdown of the unit;

- regular situations of changing the mode of operation of the technological unit;

- off-nominal situations due to the equipment failures or technological parameters alterations.

Portfolio

Complex simulators

Automated training system

Advanced process control systems

Complex simulator

Automated training system

Complex simulators

Automated training system

Useful Materials

Video