Advanced process control system

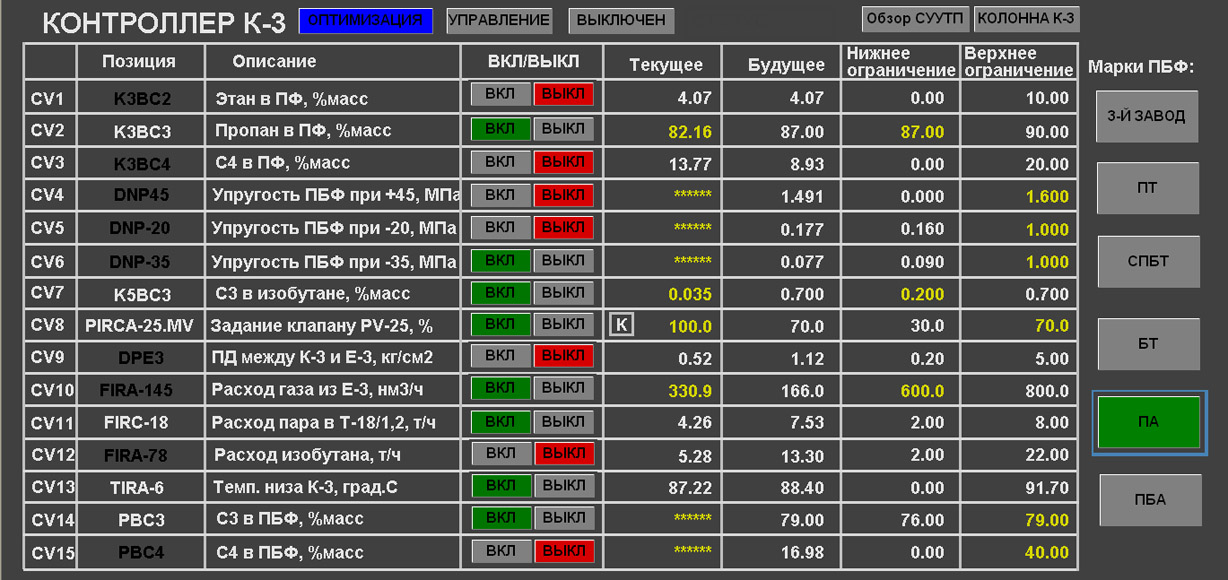

The Advanced Process Control (APC) system is based on multivariable control using Model Predictive Control (MPC) models. Traditionally, with advanced control systems, virtual analyzers are introduced to calculate non-measurable parameters of the control object.

When introducing an improved control system, models of mass flows, heat balance, and a static model of measured parameters are developed for each technological object (process).

Key advantages of implementing an SUMS for oil refineries and chemical enterprises:

- increase in productivity by 1-5%

- increasing the efficiency of the technological process by 2-10%

- reduction of energy and steam consumption by 3-10%

- reduction of losses of valuable products 1-5%

Portfolio

promzona, Tobolsk, Tyumen region, 626150

Complex simulators

Automated training system

Advanced process control systems

75, Severnoe shosse, Cherepovets, Vologodskaya obl., Russia, 162622

Complex simulator

Automated training system

11, Osipenko st, Novokuibishevsk, Samara region, 446207

Complex simulators

Automated training system

Useful Materials

Video

Share

The system provides the operator with a generalized understanding of the state of the object, which is based on a mathematical analysis of the current technological parameters of the installation.